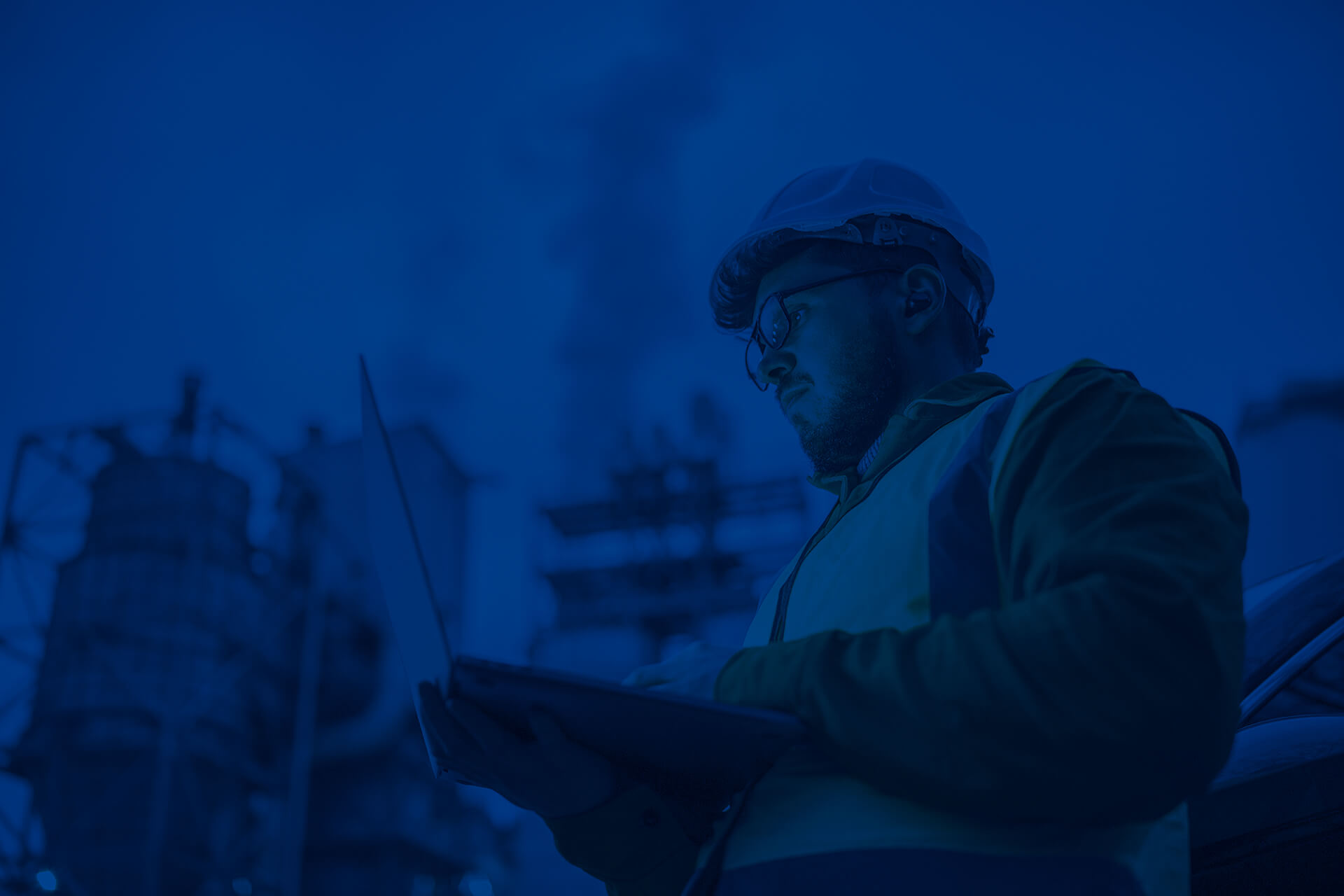

Advitech is expanding its capability and connection in the acoustic engineering field, with the addition of Rong Li to the team. As a recent graduate, Rong brings a fresh and innovative perspective to the team.

Emergent Group believes in big picture thinking. We approach challenges creatively, collaboratively and with agility. Our specialised engineering and technical sciences companies bring together a strategic blend of expertise, commercial and social acumen to deliver innovative solutions.

When you appreciate complexity, when you assemble the right people with the right skills who are motivated to succeed, you’ll find a solution.